Clothing factories struggle to restart in Bangladesh as situation worsens

According to AFP, the recent outbreak of university student demonstrations in Bangladesh spread to more than half of the country, the country is now almost in a state of total disconnection.

Image Source: Sourced from the Internet

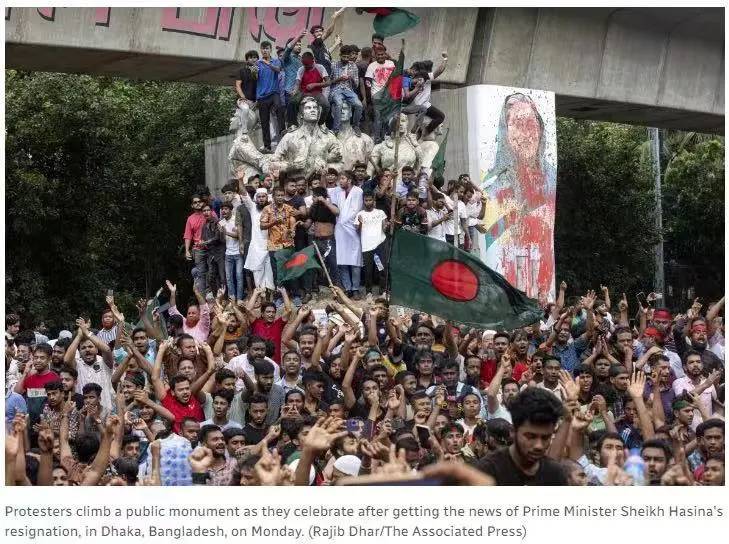

Bangladesh outbreak of demonstrations

Some foreign trade sources said that the recent communication with Bangladeshi customers is no longer stable, “basically in addition to the international phone can be connected (but the signal is very poor), other instant messaging software can not be contacted, our subsequent shipment plans have been suspended.”

It was reported that the main cause of the demonstration riots was university students' dissatisfaction with the privilege of civil service recruitment. Despite the government's announcement on July 10 that it was suspending the recruitment quota system, the protest demonstrations have not ended, and due to the unending unrest in the country, Bangladesh's Internet and SMS services have been suspended since last Thursday, resulting in a nationwide disconnection that has forced local connections with the diaspora to be disrupted as well. As the violence and social unrest escalated, the government imposed a nationwide curfew.

This draconian measure has paralyzed Bangladesh's ports and logistics system, leaving more than 80,000 containers of cargo stranded at the ports, unable to be shipped out successfully. This is undoubtedly a huge blow to the global supply chain that relies on on-time deliveries.

Image Source: Sourced from the Internet

As the world's leading exporter of textiles and apparel, Bangladesh stood as the second largest textile and apparel exporter with an export revenue of $47.38 billion from apparel in 2023, further widening the gap with Vietnam. However, will the world's second largest garment exporter now be able to maintain the confidence of international buyers, and will brands such as H&M, Zara and Walmart turn to competitors such as Cambodia and Vietnam?

Bangladeshi garment makers have reportedly shifted to expensive airfreight in the face of surging customer demand as curfews have hampered shipping by sea, but buyers are unwilling to bear the extra cost. Even customers who are willing to use air freight are demanding a 15 to 20 percent cut in prices. Curfews imposed by the local government and Internet disruptions have had a huge impact on most transport services, resulting in about 3,000 tons of air cargo not being dispatched.

Image Source: Sourced from the Internet

The vice president of the Bangladesh Garment Manufacturers and Exporters Association (BGMEA) said he had to ship 80,000 pieces of goods back to Dhaka from the port warehouse in Chittagong.The chairman of the Tusuka Group said his company had so far spent about Tk320 million (about Rs28.218 million) to transport the goods by air because of the failure to dispatch them by ship in time.

However, the problem goes far beyond that.BGMEA held a meeting with global apparel buyers, requesting not to automatically generate discounts in case of delayed shipments to avoid reducing revenue. Exporters say that the system of major buyers automatically generates discounts of 5-10 percent if shipments are delayed by more than 15 days.

The current situation shows that Bangladesh's garment manufacturing industry is facing unprecedented challenges. Strikes and social unrest have led to the “indefinite” closure of 150 factories, out of a total of 3,500 garment factories in the country, many of which are Chinese-owned. As the situation continues to deteriorate, the future of Bangladesh's garment manufacturing industry is uncertain.

The deterioration of the situation in Bangladesh not only affects the local garment industry, but also has a profound impact on the global supply chain.

There are increasing signs that the transformation of the global apparel manufacturing industry is imminent. Vietnam's non-market economy status as well as the return of Foxconn in India are reminding us that the simple transfer of production can not completely solve the problem, the digital transformation of the manufacturing industry is the key to the future.

Digital transformation means that companies need to rely on smart manufacturing technologies to improve productivity, reduce costs, and enhance supply chain resilience. In this process, digital management systems, automated equipment and smart logistics will become key tools for companies to remain competitive. With the growing demand for responsive and efficient supply chains in the global marketplace, Digital Intelligence Transformation is no longer optional, but a path that must be taken.

-------- END --------